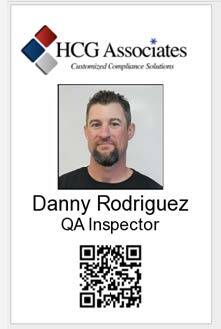

HCG Associates TraQR Cert Software

Efficient – Easy To Use Employee Certification System

Regulators require having immediate access to your current certifications. Onsite Job Safety Managers will not allow work to be performed if certifications are expired. As a result, employees find themselves scrolling through their phones to find a copy of the requested certification card. Avoid the hassles of certification management by leveraging QR technology in HCG Associates TraQR Certification Software

HCG Associates TraQR System:

- Customize the documentational content contained within the system

- Advanced notification of certifications before they expire, sent to employee and EHS Manager

- Option to include Emergency Information: Emergency Contact and more

- Full training to ease implementation

Upcoming Events

1-hour live webinar to discuss changes in place and what to expect from OSHA in Biden Administration

Topics: New OSHA National Emphasis Program, recordkeeping related to COVID, and inspections

Main Conference: May 24-26 Professional Development Courses: May 22, 23, and 27 Annual Conference for Occupational and

Crafting a PSM Program

Process Safety Management (PSM) “Programs” should reflect how a facility is adhering to OSHA and EPA requirements in regard to the facility’s covered process chemical. The program should not be a description of what should be taking place at the facility but should reflect what is actually taking place. The most important thing to remember is that State and/or Federal Auditors will hold you to the standards that are outlined in your PSM program.

There are facilities that are 100% compliant with OSHA PSM and EPA Risk Management Plan (RMP) requirements, but many are not. It is the responsibility of the facility, or the PSM Contractor, to develop a “program” that accurately reflects the facility’s commitment to the mandated programs. Commitment levels vary greatly, which is why it is critical to designate a role responsible to review and update your written program to reflect what is happening at the facility.

The two (2) most important takeaways are:

- Programs need to be crafted to reflect what the facility is doing. For example, having a Mechanical Integrity program element that states the facility completed their annual Ammonia Refrigeration Safety Inspection Checklists when they did not, could result in an audit finding with a sizeable accompanying fine.

- Non-compliant facilities need to be guided towards full compliance and adopt missing program requirements.

0 Comments